Cutting-Edge Navigation Technology by Sperry Marine

Sperry Marine, a renowned navigation solutions provider, will deliver innovative navigation systems for four SAL Heavy Lift vessels under construction at WuHu shipyard in China. The state-of-the-art navigation package includes Sperry Marine’s VisionMaster Net bridge, NAVIGAT gyrocompass, and NAVIPILOT 4500N autopilot. The systems ensure safe and efficient navigation and reduce through-life costs, highlighting the embodiment of next-gen navigation technology.

The VM Net bridge system, designed with connected navigation in mind, allows remote support, minimizing the need for on-site service calls. This design paves the way for leveraging ‘big data’ on the vessel, ultimately boosting operational efficiency.

Gyrocompass and Autopilot Systems Enhance Performance

The NAVIGAT 3500 fiber optic gyrocompass offers superior pitch and heave information, essential for safe operations under loaded conditions. As part of the NAVIGAT family, these compasses deliver outstanding heading measurements in all dynamic conditions. Additionally, they integrate seamlessly with Sperry Marine’s CompassNet, the industry’s first networked heading management system. Enhanced fuel efficiency is another perk, as NAVIGAT 3500 supports course optimization via Sperry’s NAVIPILOT 4500N autopilot.

The NAVIPILOT 4500N, a member of the NAVIPILOT series of autopilot systems, aims to provide improved course-keeping while reducing fuel consumption and lessening bridge workload.

Environmentally Friendly Features for SAL Heavy Lift Vessels

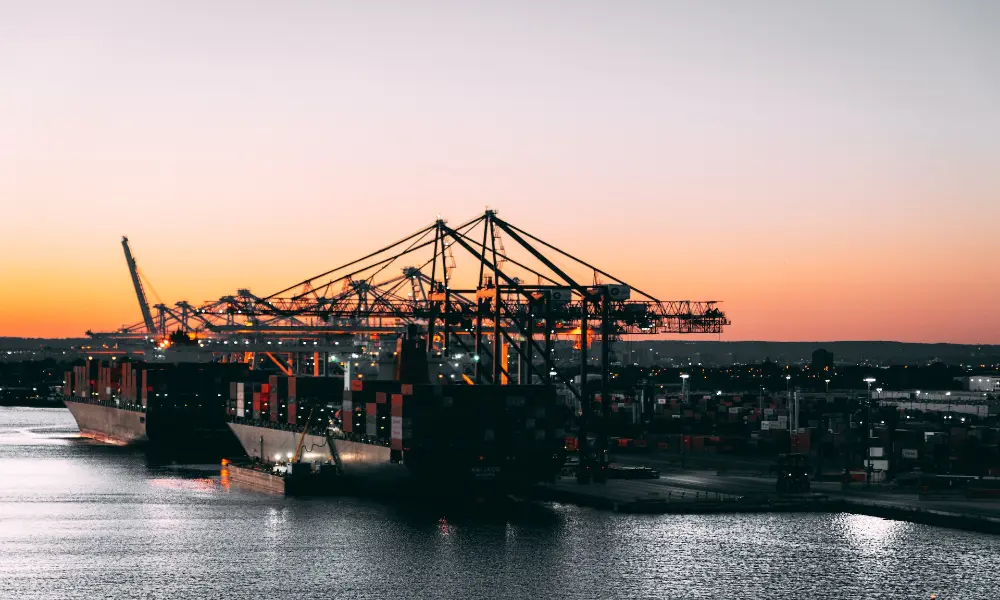

The new vessels from SAL Heavy Lift showcase cutting-edge, environmentally conscious features, such as methanol-ready propulsion systems and zero-emission port operations through ‘cold-ironing,’ connecting them to shoreside electricity. Moreover, powerful, fast, and fully electric cranes flaunt an impressive 1,600-tonne lifting capacity.

Dr. Martin Harren, owner, and CEO of SAL Heavy Lift, emphasized that the ORCA-class ships are designed to be the most efficient in their class, thanks to their reduced fuel consumption and minimized carbon emissions. He expressed confidence in Sperry Marine’s ability to exceed SAL’s demanding requirements through the deployment of advanced navigation systems.

Collaboration for Highly Specialized Ships

James Collett, Managing Director of Sperry Marine, conveyed that their agreement with SAL Heavy Lift demonstrates Sperry Marine’s capacity to support new building programs while prioritizing safety and vessel efficiency. He emphasized that success in equipping such specialized vessels relies on a blend of technical expertise and close collaboration between SAL and Sperry Marine’s global teams.

As flexibility, efficiency, and sustainability become increasingly critical in modern shipping, the partnership between Sperry Marine and SAL Heavy Lift sets a new standard for navigation systems in heavy lift vessels. The integration of cutting-edge technology marks a significant step toward shaping the future of the maritime industry.