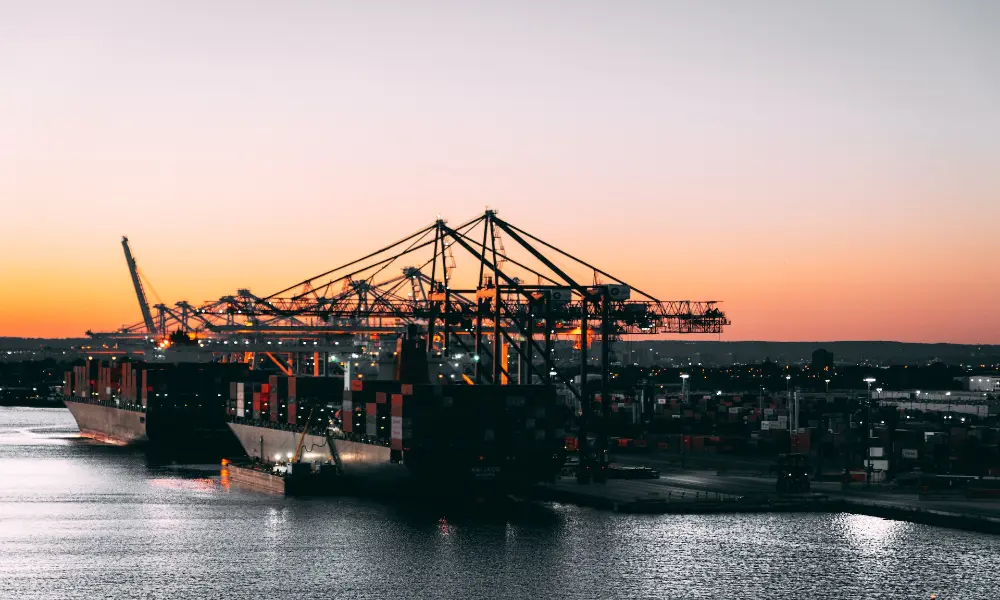

Pelagus 3D, a major innovative force that is set to disrupt the international maritime and offshore services market, premiered last Friday in Singapore, showcasing a 3D-printed spare part by CCO Håkon Ellekjær. This venture is a synergistic alliance between industry heavyweight Wilhelmsen and engineering juggernaut Thyssenkrupp, announced on September 29.

Defining a New Era: The Vision of Pelagus 3D

As a brainchild of its parent companies, Pelagus 3D’s ambition is to pave the way as the most comprehensive, on-demand digital manufacturing associate in maritime and offshore domains. This venture capitalizes on Additive Manufacturing (AM), or 3D printing, to expedite the delivery of maritime spare parts, thus optimizing time efficiency and cost-effectiveness. This innovation enables clients to maintain their vessels’ seaworthiness while adhering to an operational timeline.

Innovating with Additive Manufacturing

Regardless of the industry, time is money, and with advancements in AM, maritime and offshore spare parts will be accessible more swiftly, allowing operations to surge ahead. This groundbreaking approach ensures minimal waiting periods, hence maintaining operational momentum.

The novel establishment benefits immensely from Thyssenkrupp’s technological sophistication in additive manufacturing and its expertise from Tech Centers based in Singapore and Germany. Thyssenkrupp Materials Services also offers invaluable input in establishing digital supply chain solutions and platforms.

Promoting Maritime Expertise

Wilhelmsen fuels this collaboration with its unparalleled maritime proficiency, providing insight into the needs of modern fleet managers and supporting the delivery of an extensive selection of maritime products and services. This comprehensive knowledge base serves over half of the global merchant fleet.

Pelagus 3D features a secure digital platform that acts as a conduit between vessel managers and Original Equipment Manufacturers (OEMs). The versatility of Pelagus 3D lies in its access to various printing technologies from a global network of partners, enabling it to deliver highly specialized engineering capabilities at cost-effective rates.

Technology as the Growth Driver: Taking Maritime Industry to the Future

Pelagus 3D, headquartered in Singapore, boasts a balanced 50-50 ownership division between its founders. CEO Kenlip Ong hails Pelagus 3D as a game-changer, notably enhancing the reach to critical marine parts and solutions to facilitate international trade and transportation.

Underlying the business model is a solid foundation of engineering expertise and maritime experience. Pelagus 3D is certain to continue the tradition of innovative solutions that have characterized both Thyssenkrupp and Wilhelmsen.

Beyond Maritime Borders: Expanding into Other Industry Sectors

Pelagus 3D seeks to alleviate pain points in the maritime and offshore sectors, such as obsolescence and long lead times for critical parts by offering on-demand production. Looking beyond maritime, Pelagus 3D aims to meet the needs of various industries, ensuring supply chain resilience, diminished waste, and inventory cost, and contributing to environment-friendly and sustainable goals.

The announcement of Pelagus 3D’s launch marks another milestone in the maritime industry’s digital transformation journey. Singapore, for instance, continues to harness technological advances to optimize maritime operations.

Assistant Chief Executive of the Maritime and Port Authority of Singapore, Kenneth Lim, suggests that additive manufacturing aligns closely with Singapore’s vision of becoming the top maritime hub. Furthermore, Pelagus 3D’s establishment promises new business and employment opportunities and sets the stage for amplifying AM innovation and adoption.