Reinventing the Wind Turbine

A collection of Japanese corporations has joined forces to revolutionize the concept of floating offshore wind turbines. The project promises not only a more efficient manufacturing process but also a significant reduction in both construction and maintenance costs. Their brainchild is a vertical axis wind turbine that, they predict, will herald the next era in renewable energy technology where factors such as resilience to harsh weather conditions and suitability for floating turbines are critical.

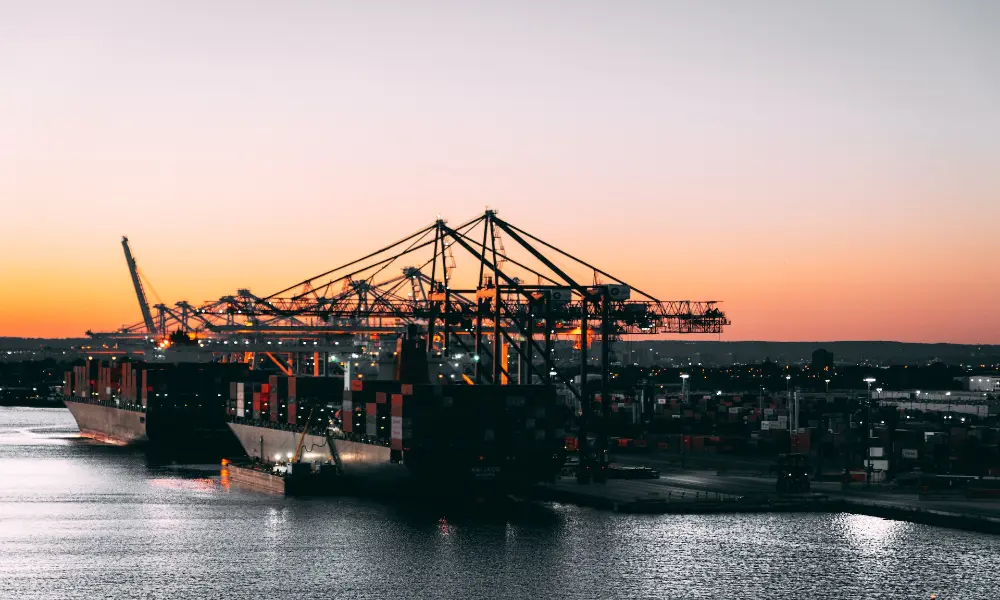

Traditional horizontal-axis floating wind turbines bear a significant downfall – a high center of gravity. These mechanisms necessitate a sizable and costly floating structure for stability, particularly in harsh conditions like typhoons. Turbine towers can reach dizzying heights of nearly 500 feet, a feature that not only escalates maintenance costs but also introduces installation challenges including the need for specialized vessels and expensive port infrastructure.

A New Wind Power Paradigm

The vertical-axis wind turbine challenges the status quo by increasing power generation efficiency and reducing the costs associated with installation, operation, and maintenance. To achieve this, the turbine employs a collection of marginally smaller paddles, with a maximum height of roughly 360 feet. Their strategic positioning closer to the surface allows the paddles to tilt up to 20 degrees while maintaining output, thus revolutionizing wind power production.

The construction of the blades incorporates a continuous pultrusion method, utilizing a molding process that forms composite materials with carbon-reinforced plastics. Additionally, the blades are fabricated in lengthwise sections of uniform cross-sectional shape, obviating the necessity for expansive manufacturing facilities. Besides, these blades are notably easier to transport compared to traditional large wind turbine blades.

A Unifying Force for Wind Energy Innovation

This invention is the brainchild of an inspired coalition of innovators: J-Power, Osaka University’s Graduate School of Engineering, and Albatross Technology, a firm dedicated to developing ocean renewable energy technologies such as floating offshore wind turbines. These initial studies have paved the way for further collaborations with shipping giant Kawasaki Kisen Kaisha as well as Tokyo Electric Power and Chubu Electric Power.

The overarching goal of this union is to develop a small-scale experimental floating-axis wind turbine designed for trials in Japan’s coastal waters. Once the plausibility of the analysis and design method is established, a more substantial-scale offshore demonstration project will be launched.

Japan’s Offshore Wind Issue Solving Game Changer

Described by insiders as a “game changer,” this unique design concept seeks to provide solutions to the challenges facing offshore wind technology in Japan, and beyond. Despite Japan’s Sea having dimensions resembling the North Sea, which is the beating heart of Europe’s offshore wind industry, the Seto Inland Sea poses a challenge due to its greater depth.

Implementing wind turbines with fixed foundations even a few kilometers into Japan’s coastal waters proves extremely challenging. This is due to the country’s exposure to harsh weather and sea conditions like typhoons. However, the new wind technology can maintain its maximum output even while tilted, proving it can significantly contribute to Japan’s future energy needs.