A Fresh Perspective in Offshore Wind Farm Logistics

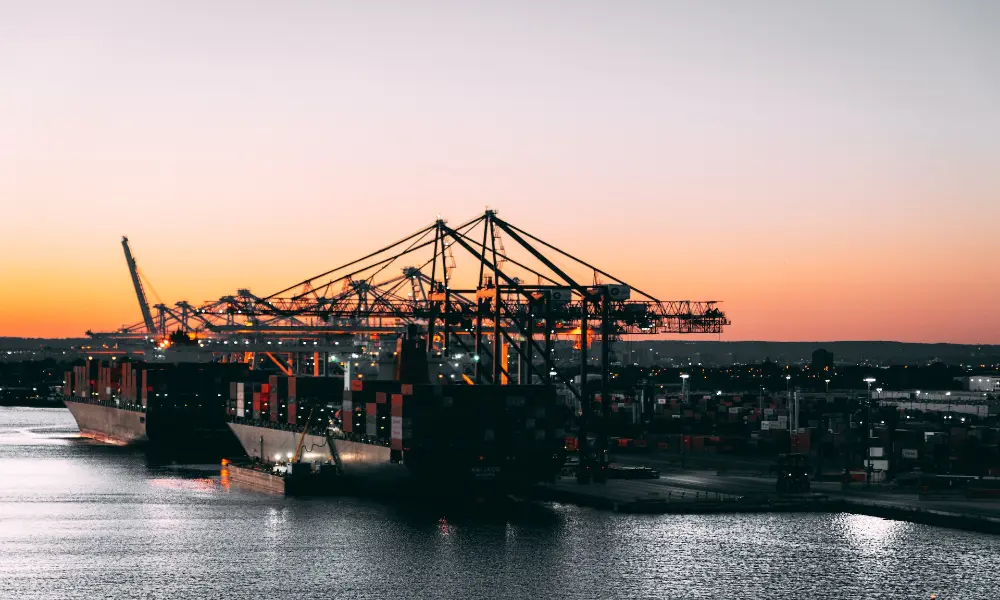

In the burgeoning sector of offshore wind farm logistics, the newly established firm HLP has emerged as a game-changer. The company, founded in 2021, is aimed at revolutionizing the way offshore wind farm logistics have been handled thus far. HLP focuses on addressing the existing lacuna in terms of the capacity needed to keep up with the skyrocketing demands of the wind farm installation boom.

Traditionally, developers have relied on a blend of accessible crane capacity with tugs and barges for out-loading jackets that are then installed by heavy lift vessels. With the industry projected to expand, increased demands on lifting, marshaling capacity, cargo vessels, and supporting equipment are expected.

HLP’s Innovative Process

What sets HLP apart is its inventive approach to logistics management. The company has developed a process leveraging state-of-the-art, fully electric ring cranes to manage components at the marshaling port. These are then transported onto a dynamically-positioned flat deck carrier for the delivery of jackets to the installation vessel. Not only does this combination amplify efficiency, but it also slashes overall costs by up to 60% compared to conventional methods.

The HLP ring crane is specifically made to enhance the pre-assembly handling of jackets at the quayside. The unit has a lifting capacity of 5,000 tonnes, transported to the center of a flat deck carrier, making loading possible under any tidal conditions and during favorable weather.

Optimizing Logistics with the DP Flat Deck Carrier

Using the larger, dynamically-positioned (DP) flat deck carrier could drastically minimize trips to the site due to heightened carrying capacity. This carries a substantial advantage over using a traditional North Sea barge. The DP carrier can complete tasks at a higher speed and offer operation within a larger weather window, thus implying a decreased risk of offshore collision. As an added advantage, incidental costs related to ongoing storage, port fees, fuel, mobilization, handling, and barge and tug standby are noticeably lessened.

Reshaping the Industry

HLP puts forth an evolutionary approach, prompting industry insiders to rethink their methods in wind farm marshaling. As jackets increase in size from 1,000 tonnes to almost 5,000 tonnes, the opportunity for cost and time savings, not to mention risk reduction, becomes more apparent. As HLP Managing Director Alex Fyfe suggests, it’s time for a 21st-century solution for a 21st-century industry.