The world’s campaign for sustainable energy is progressively taking shape, significantly impacting wind farm developments across the globe. Alex Fyfe, the managing director of the UK-based firm, Heavy Lift Projects (HLP), envisions a new strategy involving a blend of a flat deck barge with HLP’s advanced ring crane concept, aiming to drive down both the project timeline and cost.

The Surge in Windfarm Deployment

Energy generation from wind farms is poised for continued growth, expected to hit 320GW by 2030 and skyrocketing to 1,800GW by the five-decade mark. These forecasts project an annual installation increase, with 54.9GW anticipated in 2030 and a staggering 87.1GW by 2050.

However, international industry leaders, like Ben Backwell, CEO of the Global Wind Energy Council, caution that this promising trajectory may hit stumbling blocks without significant investments in capacity, plant infrastructure, training, and human resources.

Changing Times and Windfarm Infrastructure Requirements

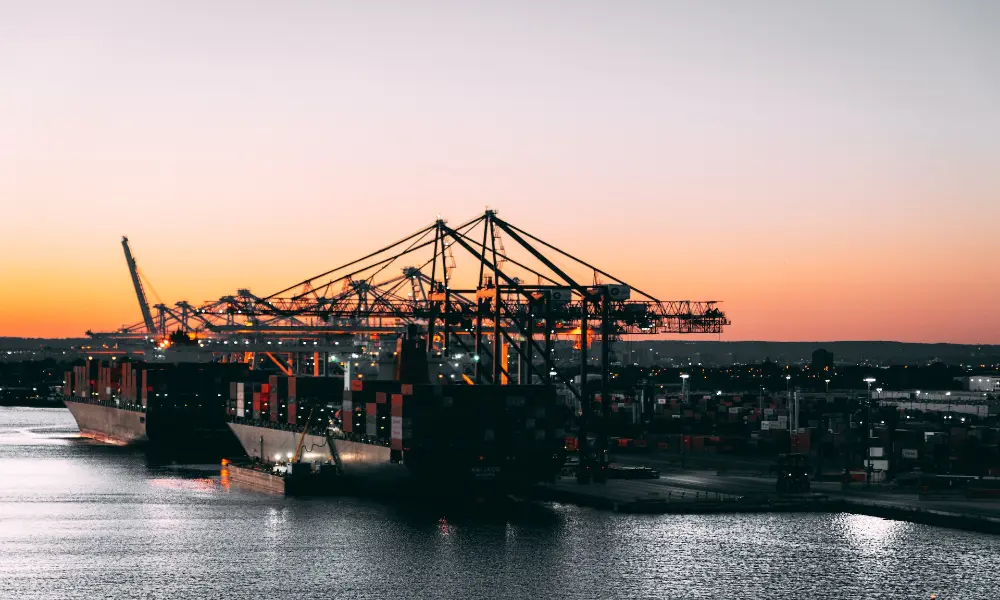

According to HLP projections, the surge in wind turbine dimensions necessitates a rethink of existing strategies. As these mammoth technologies take up more and more space in ports, there’s an increasing need to innovate handling and delivery mechanisms suitable for this new generation of components.

HLP’s proposition? Pairing its state-of-the-art ring crane, capable of processing incoming heavy-weight components, with a flat deck carrier for seamless delivery to the installation vessel. Estimates suggest that merging these two technologies can slash project timelines by as much as 60%.

Capitalizing on New Opportunities

HLP sees a massive potential in the new landscape to radically rethink conventional wind farm deployment strategies. Current approaches hinge on costly combinations of barges and tugs. However, they face challenges such as slow speeds, small weather windows, offshore station maintenance requirements, and an overall high expenditure rate due to the sheer volume of equipment needed.

HLP envisions a Dynamic Positioned (DP) flat deck vessel capable of carrying more jackets per trip. Even utilizing a dual-vessel model, HLP sees a potential cost reduction compared to the existing tug/barge setup.

Embracing the Potential of the Ring Crane

Additionally, HLP proposes the use of its groundbreaking ring crane technology to optimize the delivery system. This game-changing crane is capable of lifting over 5,000 tonnes at a 60m distance while operating efficiently regardless of tide levels.

Fast mobilization allows the crane to be temporarily utilized elsewhere during project downtime, further maximizing the use of resources and drawing extra revenue. Despite leading the industry towards uncharted territories, HLP’s visionary approach is an evolution, not a revolution, and paves the way for a sustainable and efficient future in wind farm installation.